Following major collaborations with BMW Group, CEER Motors, and Porsche, Rimac Technology continues to innovate while scaling up to produce tens of thousands of units monthly, maintaining cutting-edge technology.

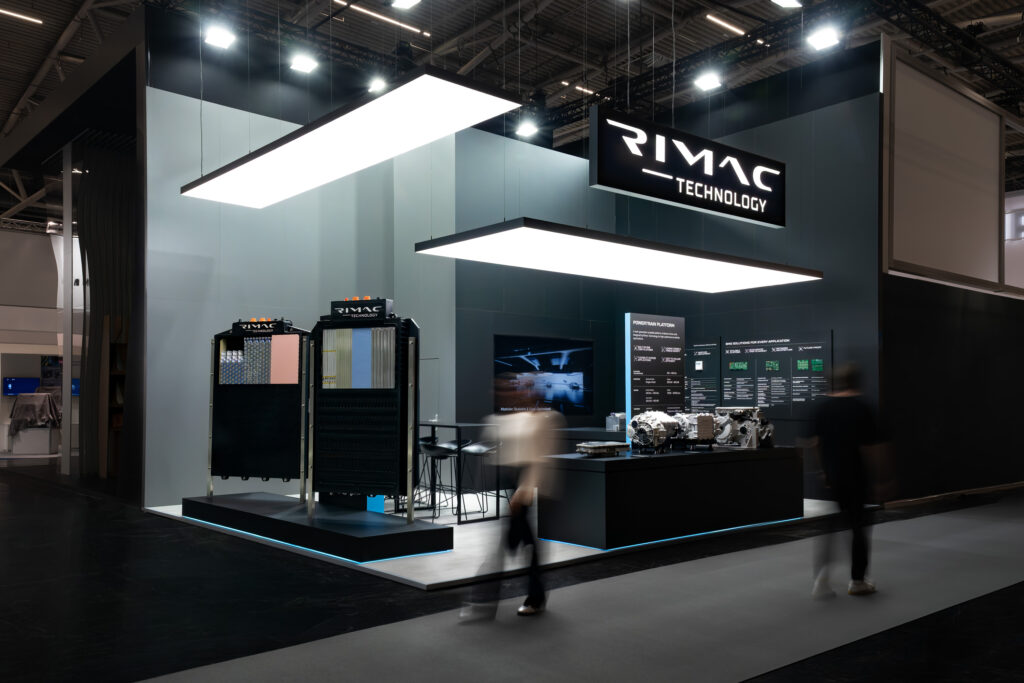

At the recently concluded IAA Mobility Show (Internationale Automobil-Austellung Mobilität) held in Munich, Rimac Technology, a Tier 1 automotive supplier that designs, engineers and produces high-end, high-performamnce electric vehicle components and energy systems for other premium brands and manufacturers showcased groundbreaking battery, powertrain, and electronics platforms.

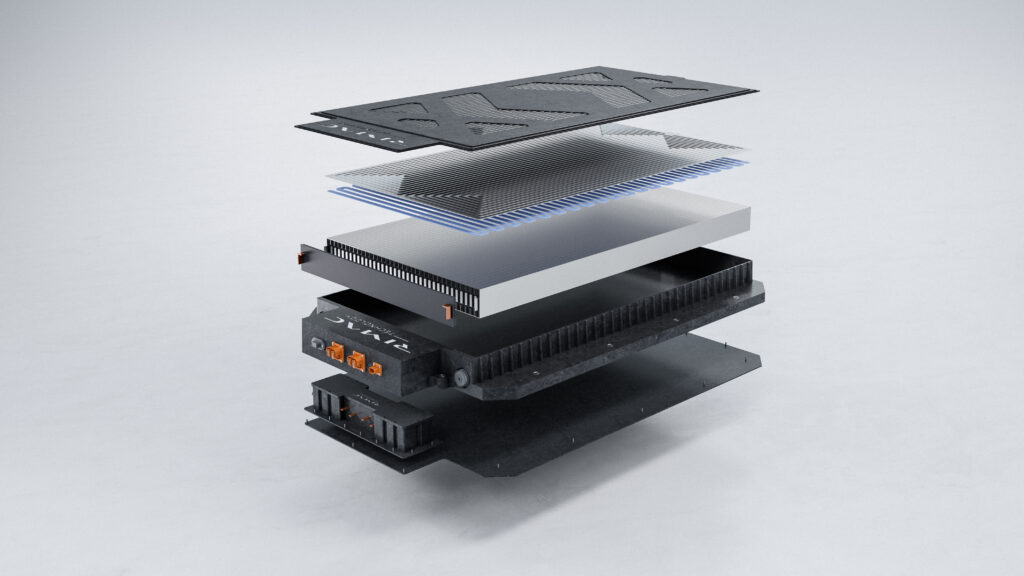

BATTERIES

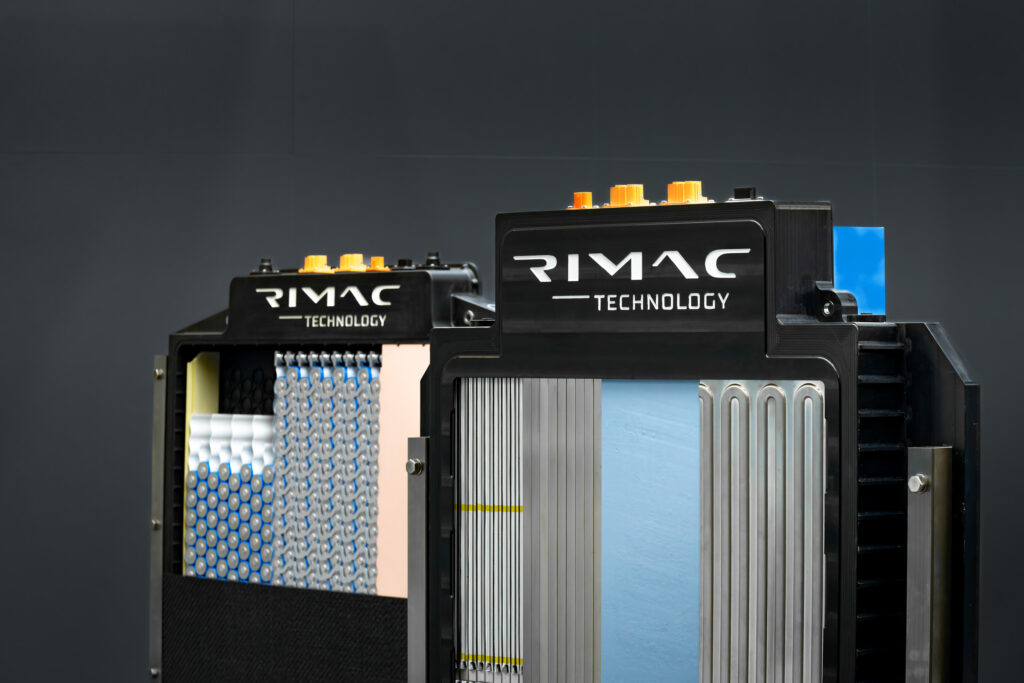

Next-Gen Technology: Developed with ProLogium and Mitsubishi Chemical Group, this advanced solid-state battery system features innovative housing, offering greater energy density, safety, and lighter weight.

Evo Technology: Using 46XX Gen2 NMC cells and a thermoplastic composite housing co-developed with Kautex Textron, this platform combines proven chemistry with advanced packaging and thermal management for high performance.

Hybrid Technology: Designed for high-energy and power-dense hybrid packs based on 46XX and 2170 cell formats, offering scalable, interchangeable configurations with advanced safety and thermal controls.

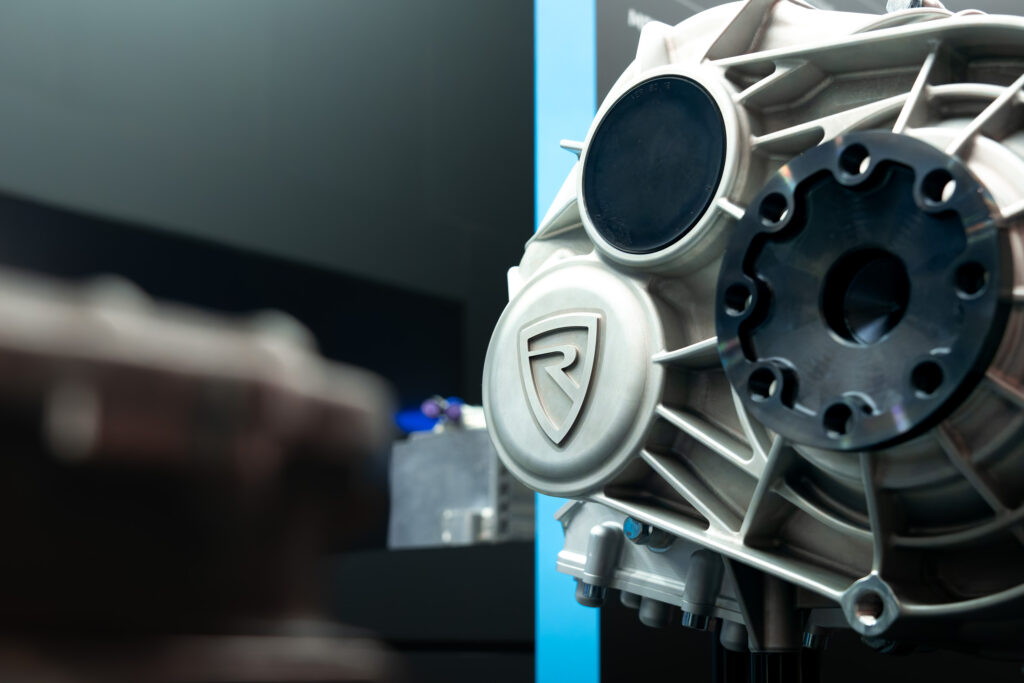

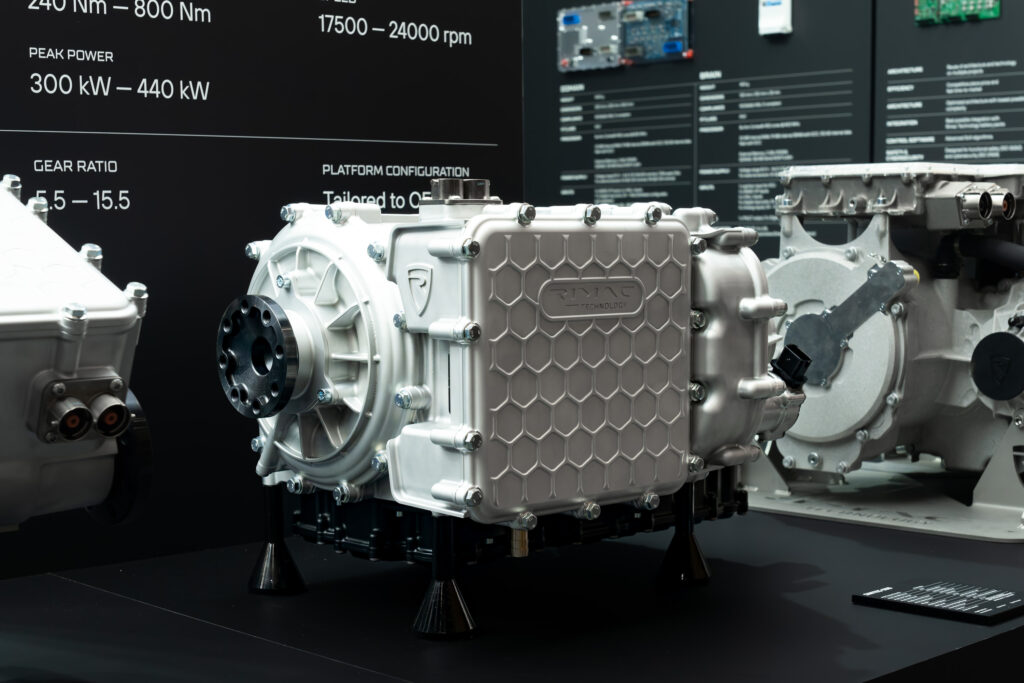

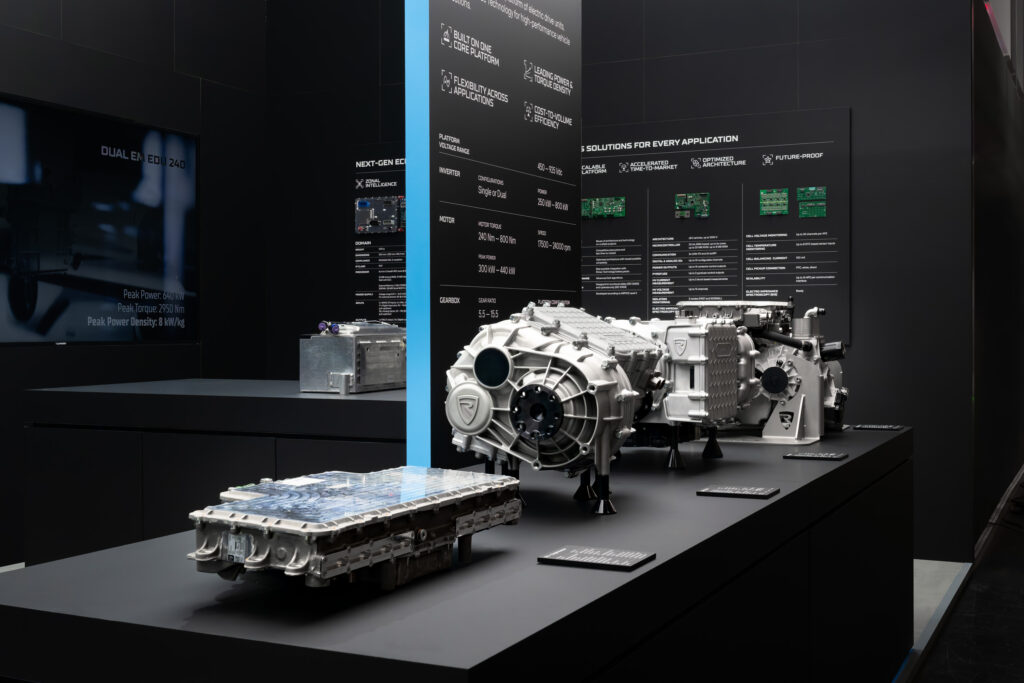

POWERTRAINS

SINTEG 300 & 550: Ultra-compact, fully integrated eAxles with power density over 8 kW/kg and torque density above 90 Nm/kg, delivering 150–360 kW and 2,500–6,250 Nm for various vehicle segments. Featuring a patented ultra-light rotor spinning to 25,000 rpm and innovative magnet design, these eAxles set new industry standards.

High Torque XXL Axle: The Dual EM EDU 550 eAxle, entering series production in 2026, offers over 11,000 Nm torque and >95% peak efficiency, supported by an automated production line at Rimac’s Zagreb facilities.

ELECTRONICS AND CONTROLS

Rimac presents domain and zonal ECUs powered by NXP’s S32E2 processors, consolidating multiple ECUs into high-performance controllers. This centralized architecture reduces complexity, cost, and weight while enabling software-defined vehicle functions from torque vectoring to power distribution, with safety, scalability, real-time performance, and OTA updates.

All showcased technologies will be produced at Rimac’s advanced Croatian facilities, including the €200 million Rimac Campus, offering over 95,000 m² of production space and high-volume manufacturing capacity.

The future of high-performance electrified mobility is looking better, brighter and more exciting!